ABOUT US

According to Eurostat data, 59 million tonnes per year of EU waste are sent to landfill and 68

million tonnes for incineration, releasing gases that are harmful to public health and

consequently to the environment.

In this context, Prodelix is a sustainable raw material alternative. Made out of urban plastic

waste not usually recyclable, it reduces on the one hand the sending of that material to

landfill or incineration and on the other the need to cut down trees.

This constitutes an excellent example of circular economy where we save waste being sent

to landfill and our customers help reduce the carbon footprint.

The circular economy concept is based on the reduction, reuse, recovery and recycling of materials, promoting the preservation of our natural resources.

OUR PROCESS

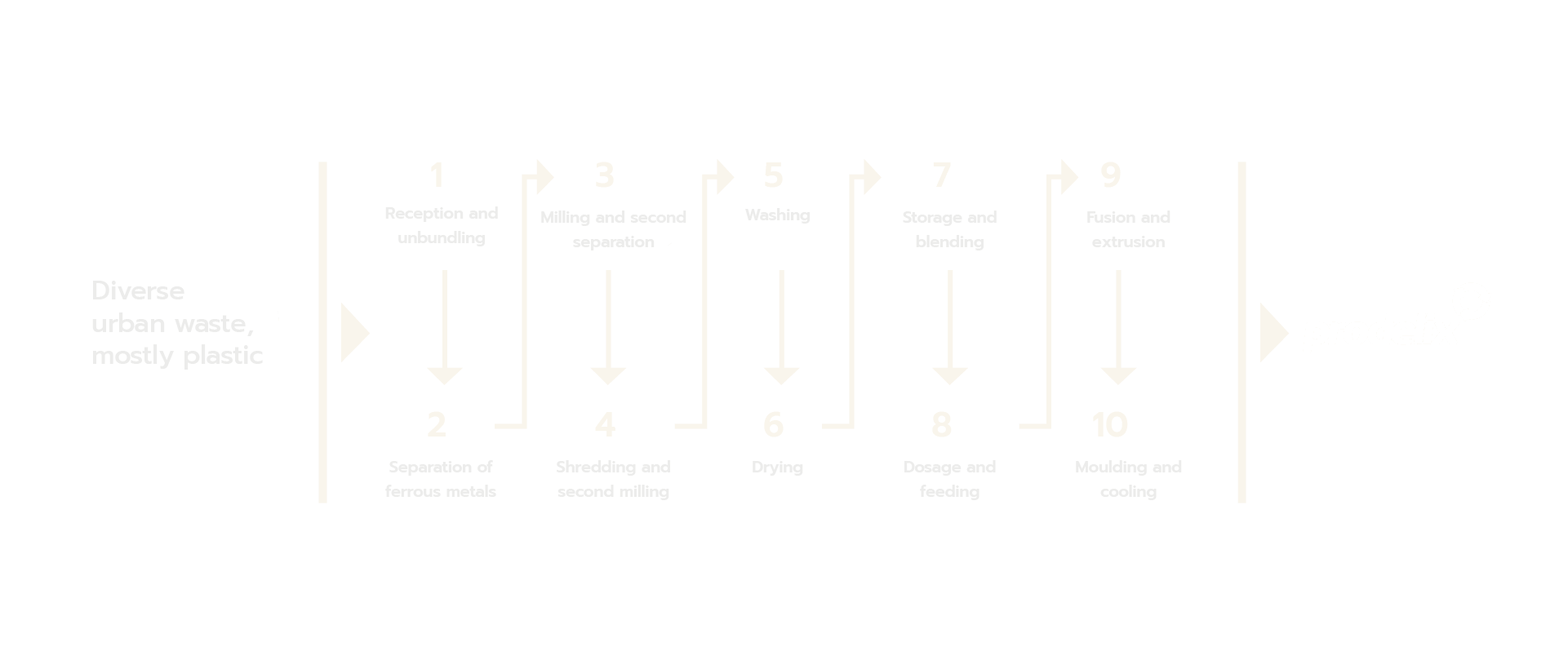

How Prodelix is created

Prodelix is the result of the fusion of a mixture of plastic and other waste that is very diverse

and difficult to recycle, extruded at high temperature and pressured into a mould where it is

cooled to form the final product.

OUR OBJECTIVE

To transform waste that is difficult to recycle into a product of value with long life, no maintenance costs, suitable for a wide variety of applications. By doing this we both avoid the accumulation of waste in landfill and help preserve natural products and raw materials (wood, metal, stone, ceramics, etc.) substituted by Prodelix.

We are concerned about the environment, be it on land or at sea, and we wish there was no plastic waste. But, as long as it exists, we want to transform it responsibly into useful, sustainable and environmentally friendly products.

Benefits for the environment

Prodelix contributes to the improvement of the environment in the following ways:

Reduces cutting down trees

Avoids the burning of waste which releases harmful gases into the atmosphere in the incineration process

- Reduces the areas occupied by landfills

- By reusing water in the manufacture process (washing, cooling) in a closed circuit

(WWTP).